When engineers need to visualize the structure of a complex system like a car, Block Definition Diagrams (BDDs) provide a clear and organized way to break it down. Unlike vague sketches or lengthy documentation, a well-crafted BDD helps teams understand components, their properties, and how they interact—crucial for designing, troubleshooting, and improving automotive systems.

In this guide, we’ll walk through the process of building a BDD for a car system, using real-world examples and best practices to ensure clarity and precision.

Step 1: Defining the Purpose and Scope

Before diving into the diagram, we need to establish what we’re modeling and why.

- High-Level vs. Detailed View

- A high-level BDD might focus on major subsystems like the engine, transmission, and braking system.

- A detailed BDD could drill into sensors, control modules, and even software interactions.

Example:

If we’re designing an electric vehicle (EV), we might include blocks like:

- Battery Pack (with attributes like voltage and capacity)

- Motor Controller (with operations like adjustTorque())

- Regenerative Braking System (interacting with both the battery and wheels)

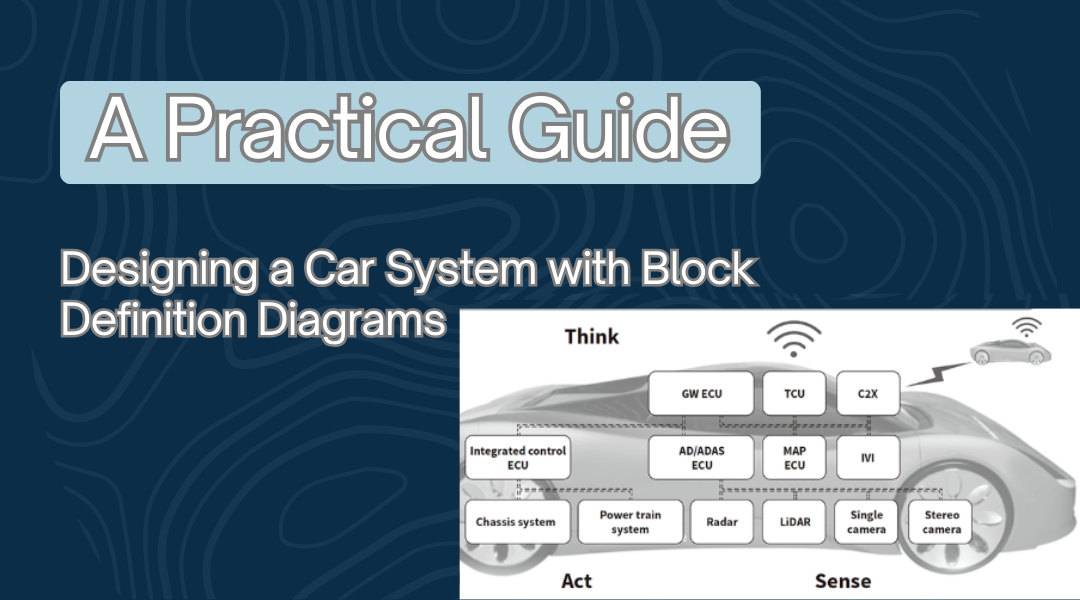

Step 2: Identifying Key Components

A car isn’t just a single machine—it’s a network of interconnected systems. Here’s how to identify the right blocks:

Core Blocks in a Typical Car System

- Powertrain (Engine/Motor, Transmission, Drivetrain)

- Chassis & Suspension (Frame, Wheels, Shock Absorbers)

- Control Systems (ECU, ABS, Infotainment)

- Safety & Comfort (Airbags, HVAC, Seat Controls)

Example:

Instead of a generic “Engine” block, we might specify:

- TurbochargedEngine (with attributes like boostPressure and maxRPM)

- HybridDriveUnit (combining electric motor and combustion engine)

Step 3: Adding Attributes and Operations

Each block should define what it is (attributes) and what it does (operations).

Example: Braking System

- Attributes:

- brakeType (e.g., “Disc” or “Drum”)

- sensorCount (for ABS)

- Operations:

- applyEmergencyStop()

- calibrateABS()

Example: Infotainment System

- Attributes:

- screenSize

- softwareVersion

- Operations:

- updateOS()

- connectBluetooth()

Step 4: Mapping Relationships Between Blocks

A car’s components don’t work in isolation—they communicate, depend on, and control each other.

Types of Relationships in a BDD

- Associations (Direct connections, e.g., Engine → Transmission)

- Generalizations (Inheritance, e.g., ElectricMotor is a type of Motor)

- Dependencies (One component relies on another, e.g., ECU needs Sensor data)

Example:

- Association: The Engine sends power to the Transmission.

- Dependency: The StabilityControl system relies on WheelSpeedSensors.

Step 5: Building the Diagram

Now, let’s piece it all together visually.

Best Practices for Layout

- Place central components (like the ECU or Engine) near the middle.

- Group related blocks (e.g., all braking components together).

- Use ports and interfaces to define how systems interact.

Example:

- A “Driver Assistance” block might have ports for:

- CameraInput (from front/rear cameras)

- RadarData (for adaptive cruise control)

Step 6: Reviewing and Refining the BDD

A diagram is only useful if it’s accurate and understandable.

Checklist for Validation

✅ Are all critical components included? (e.g., Did we forget the cooling system in an EV?)

✅ Do the relationships make sense? (e.g., Does the Transmission really connect to the Infotainment system?)

✅ Is the level of detail appropriate? (Too vague? Too cluttered?)

Tip: Run a walkthrough with mechanical and software engineers to catch missing links.

Final Thoughts

A well-designed Block Definition Diagram is more than just boxes and lines—it’s a blueprint for understanding how a car’s systems fit together. By following this structured approach, engineers can:

- Prevent design flaws early in development.

- Improve collaboration between mechanical, electrical, and software teams.

- Speed up troubleshooting when issues arise.

Whether you’re working on a traditional combustion car, a hybrid, or a fully autonomous vehicle, a clear BDD ensures everyone is on the same page—before the first prototype is even built.

Need a Starting Point?

Try sketching a basic BDD for a self-parking system, including:

- Ultrasonic Sensors (distance detection)

- Steering Control (adjusts wheel angle)

- ParkingECU (processes sensor data and executes maneuvers)

This exercise will help solidify the concepts before tackling more complex systems.